Custom Made Cartons

At Ace Packaging we specialise in custom made cartons. With an extensive range of carton styles and board grades we can custom make your ideal carton to suit the specific demands that your products require.

Our custom-made cartons give you complete control over size—from length and width to depth—so you only pay for the space you need. Manufactured from durable corrugated board, each box is precision-cut and creased to your exact dimensions, folding together easily for fast assembly. Whether you require a snug fit for delicate products or a large format for bulky goods, these cartons deliver reliable protection and a professional, no-waste packaging solution.

Check out the range of styles we offer and contact us to discuss your needs or to get a quote.

We can manufacture ANY QUANTITY at a very reasonable price, no job is too small.

For further information see the details below or check out our list of frequently asked questions about custom made cartons.

How to Measure a Carton

- When measuring custom made cartons we always measure the internal dimensions.

- Dimensions are usually expressed in Millimetres (mm) for accuracy.

- The first measurement is the Length and is always the longest side of the carton that has a flap.

- The second measurement is the Width and is always the shorter side with a flap.

- The third measurement is the Depth and is the measurement without a flap. The measurement does not include the flap.

Things to Consider When Ordering Custom Cartons

Protecting Your Products

Consider the protective material that your products require such as bubble wrap, void fill or paper and allow extra space around your products and increase the measurements or your required custom made carton.

Box Tolerances

When ordering custom made cartons there is a slight variance in size from carton to carton. The corrugated industry commit to a variance of 1.5875mm which gives a total range of 3.175mm variation.

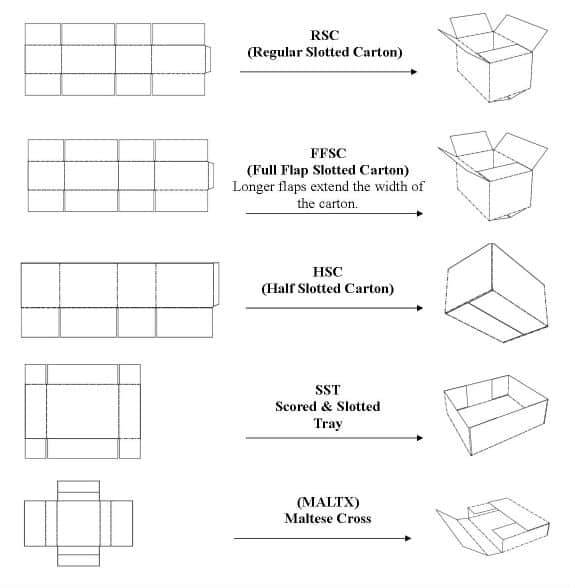

What Style of Carton do You Need ?

- Regular Slotted Container (RSC): The RSC carton style is the most common type of corrugated box. It features flaps on both the top and bottom that meet at the center of the box when folded. The flaps can be closed using adhesive tape, staples, or other sealing methods. RSC cartons are versatile and can be used for shipping and storing a wide variety of products.

- Full Flap Slotted Container (FFSC): The FFSC carton style is similar to the RSC, but with longer flaps on the top and bottom that fully overlap when closed. This provides extra protection for the contents of the box, making it a good option for heavier or fragile items. The FFSC can be sealed using adhesive tape or other methods.

- Half Slotted Container (HSC): The HSC carton style is similar to the RSC, but with only one set of flaps on either the top or bottom of the box. This makes it easier to load and unload products from the box. HSC cartons can be used for shipping or storing a variety of items.

- Snap or Self-locking Style Tray (SST): The SST carton style is a tray with a self-locking feature that eliminates the need for adhesive tape or other sealing methods. The sides of the tray fold up and interlock to securely hold the contents of the box. SST cartons are commonly used for food products, electronics, and other small items.

- Multi-Depth Auto-Lock Tray (MALTX): The MALTX carton style is similar to the SST, but with multiple score lines that allow the depth of the tray to be adjusted to fit different products. The tray automatically locks into place when folded, making it easy to assemble and seal. MALTX cartons are a good option for shipping and storing products of varying sizes.

Different Board Grades

- Choose from a wide range of board grades to suit your desired carton specifications.

- Smaller cartons are more suited to B or C Flute, larger cartons where stronger carton integrity is required select 1BC board grade.

- Available board grades are 4E, DWLE, 4B Super, 3B, 1B, 1B Super, 1WLB, 4C, 4C Super, 3C, 1C, 1C Super, 3WLC, 1WLC, 1BC, 1BC Super and 1EC Super.

- Please contact us for board grade recommendations based on your requirements.

Custom Made Carton FAQ’s

How do I measure a Carton?

When measuring custom made cartons we always measure the internal dimensions. Dimensions are expressed in Millimetres (mm) for accuracy. The first measurement is the Length and is always the longest side of the carton that has a flap. The second measurement is the Width and is always the shorter side with a flap. The third measurement is the Depth and is the measurement without a flap, this does not include the flap.

What is a carton flute?

Flute, Corrugation – This refers to the wave shapes, or ridges, that are pressed into a sheet of material that has been softened by steam. This material is then sandwiched between flat sheets of material to form corrugated fibreboard. Flute serves as protective cushioning and helps strengthen a carton. Different widths and configurations offer distinctive performance advantages.

Corrugated cartons feature either of the types below.

- B-Flute : Flute thickness is 2-3mm

- C-Flute : Flute thickness is approximately 4mm – Depending upon the stacking strength, puncture resistance , crush strength required for the carton, either B or C flute corrugations are commonly used in single-wall, general-purpose cartons. B-Flute has good puncture resistance and C-Flute has the optimum combination of both.

- E-Flute: Flute thickness is 1.5 mm – This is generally used for light applications such as Die-Cut Mailers, Shoe boxes etc.

- BC Flute – Flute thickness is approximately 8mm. This flute is a double-wall combination made from one B-flute, single-wall sheet and one C-flute, single-wall sheet. The result is a strong corrugation used when extra thickness or stacking strength is needed.

How long does it take to make a custom made carton?

A new carton can be manufactured within 8-12 working days depending on whether your carton is plain or printed and the volume you have ordered.

Short run manufacturing (Quantities of 1-499) tends to take 10-12 working days. Large run (500+) takes approximately 6-8 working days and printed cartons usually take 8-10 working days depending upon your artwork requirements.

In urgent situations a reduced lead-time can usually be met, but may include an extra charge.

Can I request a sample of my custom made carton?

A sample carton is advised for the purpose of testing the carton for size and boardgrade suitability prior to ordering. A sample can be made using our sample design and cutting facility. Samples are free of charge in the majority of cases.

Stock Samples of most cartons are available for Free. Best to try before you buy!

How long does it take to receive a quote for a custom made carton?

Once we have all your packaging requirements, we are able to get most quotations out within 24-48 hours, depending on the complexity of your needs. In a more urgent situation please contact us.

What do I need to let you know for you to quote?

If you are unsure of the most suited boardgrade please get in contact with us for an analysis of the most suitable board.

Which areas in Australia does Ace Packaging supply custom made cartons?

Ace Packaging supplies is based in Sydney, however we supply custom made cartons Australia wide.

Freight charges will apply based on the location and the quantity of custom made cartons.

Do you provide FREE quotes?

Yes we do. There is no charge for quotes and no limit to the number of quotes we can arrange.

Do you have stock size cardboard cartons?

Please contact us for a suitable size for your requirements.

Is there a cheaper rate for bulk purchasing custom made cartons?

Yes, the more you buy the cheaper the carton becomes.

As a guide the price quantity brackets are:

1-99

100-249

500-999

1000-1999

and 2000+

Is there a minimum order quantity for custom made cardboard cartons?

No, we do not set any minimum order quantities for either custom made or stock size cardboard cartons.

How many colours can I have on my custom made carton?

4 Colour process or CMYK litho-laminate print is available or 1-4 colour water based flexographic print process is available.

Is there any extra charges to print on my custom made carton?

Yes, printing plates are created for each printed carton. This is a once only charge on the initial order and is not charged for any ensuing re-run. Printing plate costs are based on sighting the artwork. Print proofs will be supplied for approval prior to production commencing.

Can you deliver my order of custom made cartons?

Please contact us for our delivery rates.